How To Wrap A Window

Installing and Flashing Windows – Your DIY Guide

Updated: Sep. thirty, 2019

Properly installed sills and flashing will withstand the atmospheric condition forever

Yous don't need to exist a professional person to install new windows - yous only need this super solid DIY guide that details how to properly install & flash new windows!

Y'all might also like: TBD

Overview

Whatever carpenter who has done remodeling piece of work has suffered through this scenario: You pull out an old flanged window for replacement and recognize the telltale signs of a leaky window: rotted framing and sheathing, even soaked insulation infested with mold. That'southward when a unproblematic window swap-out turns into a headache project, complete with a customer who'due south grouchy over a larger-than-expected neb.

Until recently, many flanged windows were installed by only cut X's in the business firm wrap and popping them in. But that led to a lot of leaks—and a whole lot of unhappy customers. Now, new materials and techniques make it possible to install windows without any worry of callbacks. For just an extra 15 minutes of effort and a few dollars worth of materials, you can make any window installation watertight and lawsuit-proof.

It starts with the rough opening

The most important function of the procedure is the "sill flashing" (Figure A and Photograph 3). It'south a piece of preformed plastic flashing or a site-built organisation (see "Site-Built Sill Flashing," below) that slopes abroad from the opening, and so any water that gets behind the siding won't collect under the window and cause issues. But crude openings provided by manufacturers don't generally allow for the thickness of sill flashing.

If you're going with pre-made plastic sill pans, add together an extra 1/4 in. of height to the R.O. If y'all're building your own sill pan, add the thickness of the siding plus 1/8 in. And if you're dealing with an existing R.O., you can try to dry-fit the window and come across if there's enough space left over for shimming and insulation. Otherwise, information technology's a proficient thought to tear out the ii-by sill framing and replace information technology with 3/4-in. plywood, and then shim as needed.

Figure A: Prep the Opening

The most important function of weatherproofing begins before the window goes in. After the house wrap is cutting, tuck the lesser flap into the business firm and install sill flashing. Then fold in the sides of the house wrap, but get out the top flap lone.

Cut the house wrap with intendance

Don't first hacking away at the house wrap, especially if you're new to window flashing. You're leap to miscut something because it's tough to encounter the bodily opening. Instead, feel the window opening through the firm wrap and mark the cuts showtime. Then slit the house wrap and tack the top and side flaps out of the manner with a staple or two (Photograph 2). Drape the bottom flap into the opening and staple it to the sill.

Go on in mind that the business firm wrap is your last line of defense confronting whatsoever water that finds its way by the siding. So if you do blow whatsoever cuts, make certain you patch them with house wrap tape.

Install the window flashing

Some window manufacturers offer sill flashing as options when you buy the window. But if not, there are plenty of aftermarket suppliers. Plan on using sill flashing. The window flashing nosotros're using comes in three parts: two preformed corners and a center department that yous cut to length to fit.

Outset by nailing the corners in place under the house wrap at the sides and over the business firm wrap below (Photo 4). And so cut the centre department to fit. The flashing is easy to cut with tin can snips. Pay attention to the raised ribs, which provide a flat surface where the window frame rests. You accept to cut the eye section and then that it overlaps the corners ane/two in. Recollect it through before you cut to make sure the ribs don't overlap.

Add together caulk at the laps and nail the flashing into identify with roofing nails. And then use your thumb to caulk the smash heads.

Time to slip the window in

Fold the house wrap sides in, staple them to the room side of the trimmers and male monarch studs, then piece off the excess on the inside of the house. Leave the top flap lone for now, just seal the overlap at the bottom corners with house wrap tape. Then get ahead with a normal installation. If you're new to the game, just follow the window installation instructions. Don't skip the corner gaskets if the window comes with them (Effigy B). They proceed out water, and leaving them off can void the window warranty.

Figure B: Window Seal Replacement Around the Window

Seal effectually the window with flashing tape, lapping the acme piece over the sides. Then fold downwardly the house wrap at the top, and comprehend the diagonal slits at the top with firm wrap record.

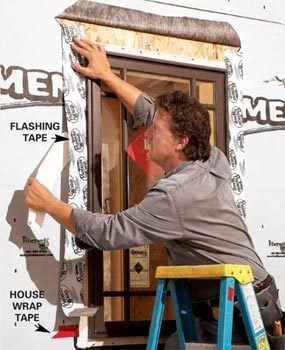

Flashing tape is the first line of defense

Flashing tape (Photo 6) is a thick, pliable, waterproof record that goes nether or over nailing window flanges, sill and top flashing, and house wrap. Available wherever you lot buy your windows, it's unremarkably sold in a 50-ft. roll of iv-in.-wide material. Apply iv-in. if you lot're siding right against the window. But if you plan to surround the window with trim, choose nine-in.-broad flashing to protect backside the seam betwixt the trim and the siding.

Cutting the tape to length with a utility knife and peel a picayune bit of the backing free and stick it to the meridian of the window. So lay it alongside the window and peel abroad the rest of the backing as you lot shine it into place. Embed it with a laminate roller for a skilful seal. For the best adhesion in cold conditions, hit the tape with a heat gun while you ringlet.

Site-Built Sill Flashing

Twenty bucks doesn't seem like much for ane window's worth of plastic sill flashing, just if you're outfitting a new house with 30 windows, 600 bucks can be sobering. Especially if your competitor isn't flashing at all! But there is an alternative. For years, carpenters have built their own sill flashing from thin-beveled cedar siding and flexible flashing tape. Rip the siding to the aforementioned width as the sill and stretch the tape at the corners to eliminate wrinkles.

Here'southward some communication. Get your bid for your side by side new window installation in showtime and tell the customer about your waterproofing system correct upward front end. Information technology'll come in handy when she asks XYZ Structure if that's part of his bid. His deer-in-the-headlights look and/ or stammering nigh how information technology "isn't important" will give yous a leg up when it's time to make up one's mind—you vs. XYZ Structure. Who would you choose?

Replacing an Existing Window

The system we're showing is for new window installation. Ideally, when y'all replace an existing window with a new 1, it should exist weatherproofed using this same arrangement. Chances are, though, that the existing windows are missing proper flashing, house wrap or even felt. The extent of weatherproofing you should consider depends on the new window'due south exposure to weather. If the window's deep in an entryway and has zilch exposure, y'all tin can skip the weatherproofing and just caulk effectually it. If the summit of the window is about an eave but the bottom is exposed to the elements, strip off the siding and focus on flashing the bottom half of the window, but ignore the top. If the window'southward out in the open, unprotected by overhangs, strip off every bit much siding as needed to expose the opening and perform the steps just as we show.

Required Tools for this Project

Have the necessary tools for this DIY projection lined up before you beginning—you'll relieve time and frustration.

Required Materials for this Projection

Avoid last-infinitesimal shopping trips by having all your materials ready alee of time. Here's a list.

Originally Published: June 24, 2019

How To Wrap A Window,

Source: https://www.familyhandyman.com/project/prevent-window-leaks-with-proper-window-installation/

Posted by: whitepaligar.blogspot.com

0 Response to "How To Wrap A Window"

Post a Comment